Pump It Free-Flowing Floor Screeds Liquid Screed Preparation Checklist

Floor Preparation for Liquid Floor Screed

Please be aware that all rooms must be sealed prior to application of Liquid Screed (windows & doors etc)

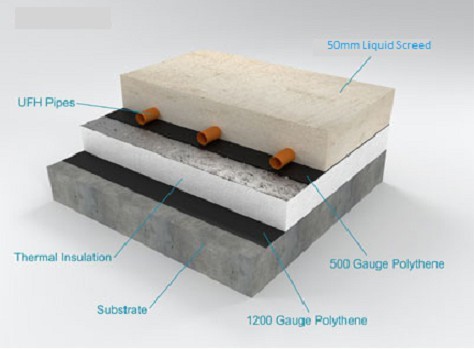

Preparation for use with Under Floor Heating:

✔ Has floor been prepped as per diagram supplied

✔ Insulation laid

✔ Plastic membrane laid

✔ Membrane to reach up perimeter walls above desired screed level and secured into place

✔ All membrane joints and joins sealed

✔ Expansion gap fitted around perimeter of room

✔ Pipes fitted and well clipped down

✔ Pipes to be water pressure tested and left filled with water prior to screed being laid

✔ All debris removed – as any bits will float on screed surface

Preparation for use with existing bonded floor:

✔ Floor to be free from debris

✔ Floor to be sealed/bonded with PVA a minimum of 24 hours prior to screed laying

✔ Expansion gap fitted around perimeter of room

Expansion Gap for Joint Movement: The edge strip recommended for use with Liquid Screed is minimum 8mm (10mm with under floor heating) foamed polythene with an attached polythene skirt, this thickness relates directly to the maximum allowable positive movement within the screed.

VAT No:129 0225 39 CPCS Approved

PUMP IT LIMITED – REGISTERED IN ENGLAND & WALES – COMPANY REGISTRATION No: 7950933